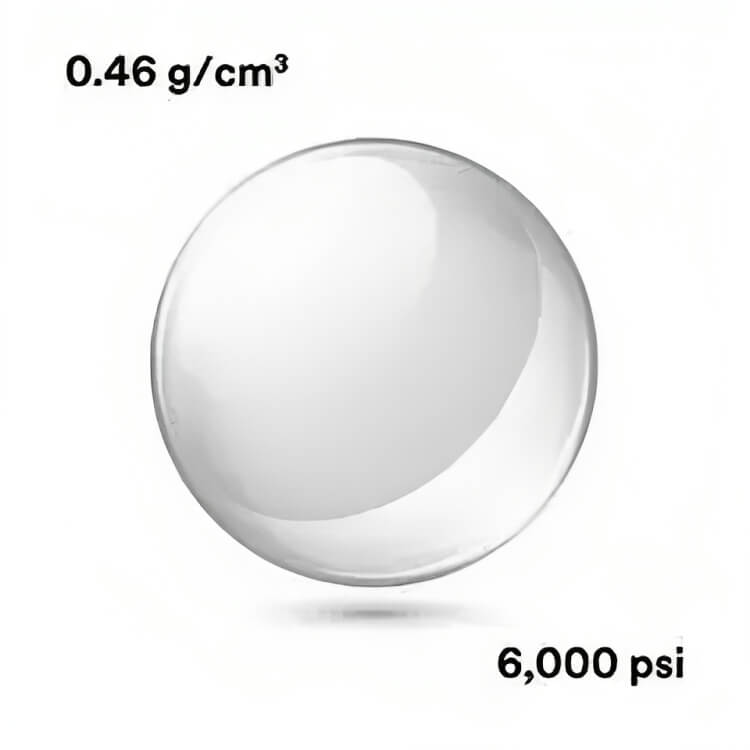

3M™ Glass Bubbles K46 are glass spheres with a typical density of 0.46 g/cc and an isostatic crush strength of 6,000 psi for good strength-to-density ratio. K46 can be used in thermoplastic compounding, extrusion processes and in insulation coatings in deep water applications. They produce strong, stable voids with low thermal conductivity, helping coatings achieve the necessary strength.

What are 3M™ Glass Bubbles?

Our 3M™ Glass Bubbles K46 are engineered hollow glass spheres made from water-resistant and chemically-stable soda-lime borosilicate glass. Like all 3M™ Glass Bubbles, our K46 glass bubbles are water and oil resistant, making them suitable for use in a number of oil and gas applications. Additionally, they are non-combustible and non-porous, so they do not absorb resin; and their low alkalinity makes this product compatible with most resins while providing a stable viscosity and a long shelf life.

These low-density hollow glass microspheres are used for many demanding applications across a wide range of industries to provide temperature and pressure resistance and to reduce part weight. For these reasons, 3M glass bubbles are a superior alternative to many conventional fillers and additives such as silica, calcium carbonate, talc and clay.

Good Strength-to-Weight Ratio

The benefits don’t end there; 3M glass bubbles K46 have thin walls and a good isostatic crush strength of 6,000 psi, making them suitable for a number of buoyancy applications, including additives in buoys and moorings — as well as applications up to 10,000 ft. / 3,000 m. below sea level. At 6,000 psi, K46 bubbles have a targeted fractional survival rate of 90% for consistent performance and greater survivability.

Pushing the Limits: a Proud History of Innovation

Hollow glass bubble technology was developed by 3M in the 1960s. Riser buoyancy modules and wet pipe flowline insulation using the first glass bubble-filled syntactic foams were capable of surviving down to 5,000 feet below sea level. Today, advancements in the strength-to-density ratio of glass bubbles enable these materials to be used down at any depth — all the way to the bottom of the ocean — more than 36,000 feet (10,972 meters).

Typical Applications

| Appearance (Unaided Eye) | White Powder |

|---|---|

| Composition | Soda-lime Borosilicate Glass |

| Crush Strength (Imperial) | 6000 psi (80% Minimum Fractional Survival) |

| Crush Strength (Metric) | 41.37 MPa (80% Minimum Fractional Survival) |

| Density Range (g/cc) | 0.40 – 0.49 |

| Factory ISO Certification | No ISO Certification information available |

| Industries | Construction, Paints and Coatings, Rubber and Plastic, Transportation |

| Net Weight (Imperial) | 2 lb, 10 lb, 125 lb, 785 lb, 825 lb |

| Net Weight (Metric) | 0.9 kg, 4.536 kg, 56.7 kg, 356.07 kg, 374.214 kg |

| Product Usage | Insulation |

| Shape | Thin-walled Hollow Spheres |

| Typical Density | 0.46 g/cc |

| Typical Median Particle Diameter | 40 µm |

Elevating Industries with Innovative Chemical Solutions for a Sustainable Future.