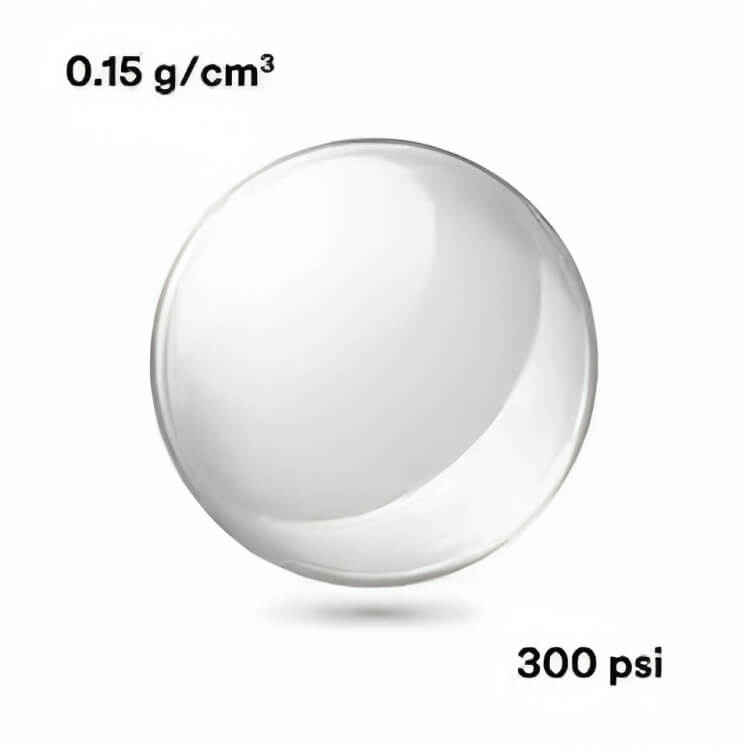

3M™ Glass Bubbles K15 are hollow glass spheres with a typical density of 0.15 g/cc and an isostatic crush strength of 300 psi. These spheres are designed for use in a variety of oil and gas applications including drill riser buoyancy modules, buoys and moorings. Our K15 bubbles produce strong, stable voids with low thermal conductivity, helping coatings achieve the necessary compressive strength.

What are 3M™ Glass Bubbles?

The general-purpose K series glass bubbles are among the most versatile and economical 3M™ Glass Bubbles. Our 3M™ Glass Bubbles K15 are engineered hollow glass spheres made from water-resistant and chemically stable soda-lime borosilicate glass. Like all 3M glass bubbles, our K15 glass bubbles are water and oil-resistant, providing better utility in underwater oil and gas applications. Additionally, they are non-combustible and non-porous, so they do not absorb resin; and their low alkalinity makes this product compatible with most resins while providing a stable viscosity and a long shelf life.

3M glass bubbles are a superior alternative to many conventional fillers and additives such as silicas, calcium carbonate, talc, clay and other materials used in demanding applications. Our low-density spheres are used in a wide range of industries to reduce part weight, lower costs and enhance product properties – making them more reliable and affordable.

Strength-to-Weight Ratio

The benefits don’t end there; although these hollow spheres have thin walls, they have an isostatic crush strength of 300 psi, making them suitable for a number of buoyancy applications, including additives in buoys and moorings. K15 bubbles have a fractional survival rate of 80% or more, at 300 psi for consistent performance.

The unique spherical shape of these bubbles offers a number of important benefits, including: higher filler loading, lower viscosity/improved flow and reduced shrinkage and warpage. Higher filler loading offers the potential for lower costs. Adding to this product’s versatility is its ability to be easily blended into compounds, making it adaptable to a variety of production processes including spraying, casting and molding.

| Appearance (Unaided Eye) | White Powder |

|---|---|

| Composition | Soda-lime Borosilicate Glass |

| Crush Strength (Metric) | 2.07 MPa (80% Minimum Fractional Survival) |

| Density Range (g/cc) | 0.10 – 0.19 |

| Industries | Construction, Mining, Paints and Coatings, Rubber and Plastic, Transportation |

| Net Weight (Metric) | 0.2 kg, 4.536 kg, 20 kg, 110 kg, 113 kg, 113.398 kg, 117.934 kg, 4309.128 kg |

| Product Usage | Buoyancy |

| Shape | Thin-walled Hollow Spheres |

| Typical Density | 0.15 g/cc |

| Typical Median Particle Diameter | 60 µm |

Elevating Industries with Innovative Chemical Solutions for a Sustainable Future.