3M™ Ceramic Microspheres White Grade W-410 are solid, engineered particles with a typical whiteness (L Value) of 90 or greater and an effective d90 particle size of 21 μm. These unique particles offer formulation flexibility and may allow formulations with lower VOCs due to lower resin demand – as well as excellent scrub and burnish resistance.

What are Ceramic Microspheres?

Our 3M™ Ceramic Microspheres White Grade W-410 are made of high-strength alkali alumino silicate ceramic with a typical d90 of 21 microns; it has a controlled particle size distribution. Formulating with these 3M ceramic microspheres allows higher filler loadings while maintaining desired properties such as viscosity control. In addition, these engineered particles are added to many paints and industrial coatings to provide scrub and burnish resistance. Due to their smaller particle size, 3M ceramic microspheres white grade W-410 are typically chosen over other 3M ceramic microspheres for their overall balance in properties. Formulators may be able to extend resin in their formulation by adding 3M ceramic microspheres and potentially reduce cost.

Abrasion, Scrub and Burnish Resistance

The benefits of the solid, high-strength ceramic microspheres come from their hardness and unique shape and size distribution; These particles deliver a number of improvements to paint performance in a variety of finishes, including eggshell or flat matte finish. One of the benefits is scrubbability since painted surfaces are often cleaned and scrubbed.

A common problem: paints can break or burnish — causing undesirable blemishes or change in gloss. A solution: 3M ceramic microspheres white grade W-410 deliver durable paint to your customers with scrub and burnish properties. Painted surfaces that use 3M ceramic microspheresW-410 offers a balance of aesthetic and durability properties. Paints formulated with 3M™ Ceramic Microspheres White Grade W-410 can be scrubbed more times before scratches, paint defects and burnishing appear. This means that this product’s excellent abrasion resistance could help protect painted surfaces against wear and tear. This is because our microspheres are strong and durable, with a crush strength of 60,000 psi (pounds per square inch) and Mohs hardness of 6.

We test starter formulations using the rigorous industry standard ASTM D2486 — a test that measures how many times a surface can be scrubbed before paint is removed. We have observed that W-410 allows formulations with better durability than W-210 as well as improved scrub and burnish over conventional fillers. 3M ceramic microspheres allow formulators to balance properties in their formulation to achieve optimal performance. Paint formulations made with 3M ceramic microspheres white grade W-410 can help the end user achieve painted surfaces that look unblemished and newer for a longer period of time.

Superior Viscosity and Easy Application

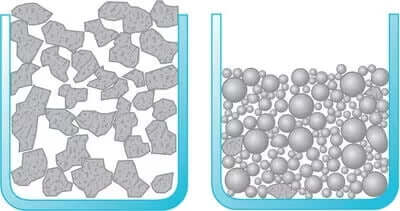

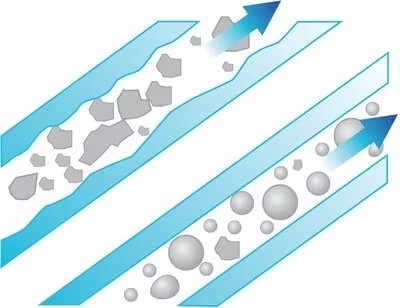

The benefits don’t end there. Ceramic microspheres have a low polymeric binder demand, meaning because of their shape and size, they do not bind with as much polymer as other fillers. This in turn allows a lower viscosity at the same loading because less of the polymer is tied up with the fillers. Because our ceramic microspheres have a unique shape, size and distribution — and fewer sites (lower surface area per volume), formulators can create paints that have lower viscosities without sacrificing filler volume. Ceramic microspheres are a low binder demand filler. Conversely, other fillers such as calcium carbonate, mica and wollastonite have fractured, irregular shapes that can cause the viscosity to increase and can cause diminished paint performance in the final coating.

Formulating for the Future

Formulating low volatile organic compound (VOC) content is an important factor in the coatings industry. Our microspheres can help manage viscosity when paint manufacturers reduce the VOC content (solvent) of their paint. By using our ceramic microspheres, paint manufacturers are able to formulate in different ways and achieve valuable coating properties. For optimal results, 3M ceramic microspheres are typically added during the grind stage of paint formulation.

Formulations with ceramic microspheres can have lower viscosity at the same filler loading as formulations containing other common fillers. Smaller spheres can fill voids between larger ones to enhance packing for higher solids and reduced costs. These ceramic microspheres can allow formulation flexibility to help manufacturers meet the demanding performance and economic targets in the coating industry. In short, our fillers enable paints that last longer and maintain aesthetic appeal. Find the superior paint performance that you’ve been looking for from 3M, a company that has helped customers incorporate ceramic microspheres into their paints and coatings for over 20 years.

Potential Applications

| Color (unaided eye) | White, powdery |

|---|---|

| Composition | Alkali Alumino Silicate Ceramic |

| Crush Strength | >60,000 |

| Density | 2.4 g/cc |

| Factory ISO Certification | No ISO Certification information available |

| Industries | Paints and Coatings |

| Median Particle Diameter | 4 μm |

| Net Weight (Imperial) | 9 lb, 50 lb, 55 lb, 1000 lb, 2000 lb, 2205 lb |

| Net Weight (Metric) | 4 kg, 22.7 kg, 24.945 kg, 453.952 kg, 909 kg, 1000.171 kg |

| Particle Size (D90 Micron) | 20 |

| Product Color | White |

| Shape | Solid Spheroids |

Elevating Industries with Innovative Chemical Solutions for a Sustainable Future.